The surface energy of the items you are labeling can range from high to low. As a general rule, the higher the surface energy the easier it is to create a bond between the label and surface. For example,

corrugated cardboard has a high-energy surface promoting easy adhesion, while plastics and coatings applied to paper or cardboard for durability can create a slick, low-energy surface making a bond more difficult. There are different types of adhesives specifically formulated to suit high- and low-energy surfaces, so these variances should be taken into account when picking an adhesive.

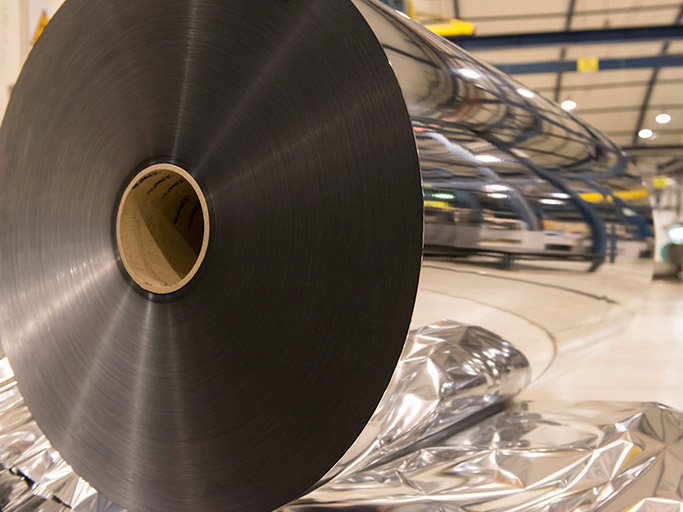

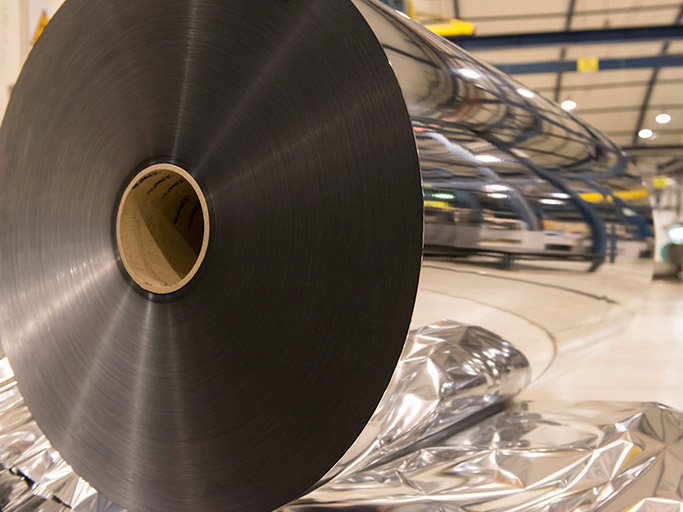

The material selected should match the characteristics of the item to be labeled. For example, a label used on a plastic squeeze tube needs to have a higher degree of flexibility than the label applied to the carton containing the tube. The most frequently specified label materials include:

White Thermal Transfer / Direct Thermal Paper – features a bright white appearance along with high resistance to abrasion and smearing, typically does not work well in wet environments

Vinyl – high-performance acrylic adhesive provides a permanent bond to a wide range of surfaces, excellent for outdoor applications and can last up to seven years, required pliability should be considered

Polyester – UL approved, designed for indoor/outdoor use; some types are temperature resistant up to 3000 F, can last 2-5 years outdoors, is chemical resistant

Polyimide – designed for barcode or alphanumeric identification of printed circuit boards, or related electronic components, for A:sn temperatures up to 10000 F

Polypropylene – designed for environmental resistance; excellent adhesion to painted metal, polyolefin and fiber drums in all weather conditions, suitable for short-term outdoor applications for six months to two years

Polyethylene – designed for use in a variety of printing applications where durability, strength, and superior printability are key, works well for squeeze bottles, lasts six months to two years outdoors

Labels may also require special characteristics such as tolerance of extreme temperatures, moisture resistance, or the ability to withstand harsh chemicals. Specially formulated coatings can be used to enhance the durability of materials used for these applications.

English

English 中文

中文 Français

Français Português

Português اللغة العربية

اللغة العربية

+86-769-88326932

+86-769-88326932